Introduction

The quest for efficient and cost-effective heat transfer solutions is a constant endeavor in industrial applications. The plate heat exchanger, known for its compact design and high heat transfer efficiency, has emerged as a preferred choice for many. This blog aims to guide you through the process of choosing the right plate heat exchanger for your specific application.

Understanding Your Application

The first and foremost step in selecting a plate heat exchanger involves a comprehensive understanding of the type of fluids involved in the heat exchange process. Different fluids have different properties such as viscosity, density, thermal conductivity, and specific heat capacity. These properties can significantly affect the heat transfer efficiency. Moreover, the desired temperature change and the flow rate are also crucial parameters. For instance, if the flow rate is high, a larger heat exchanger may be required to handle the volume.

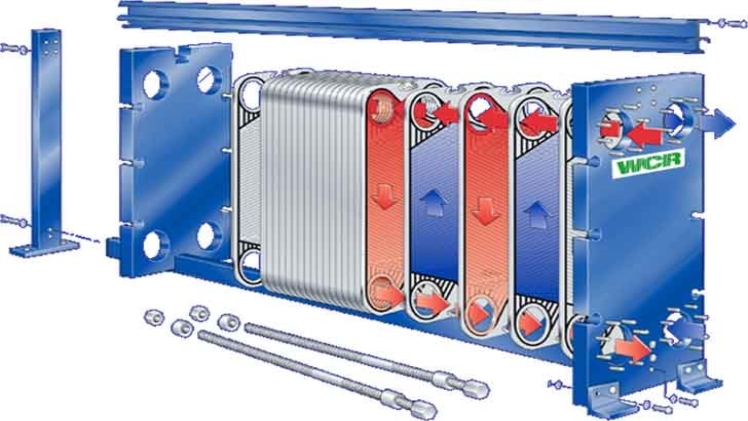

Plate Design

The design of the plates in a plate heat exchanger is another critical factor. The heat exchanger offers a variety of plate designs to suit different applications. The corrugation pattern on the plates, their size, and materials all play a role in the heat transfer efficiency and pressure drop. For example, a high corrugation angle can lead to high heat transfer efficiency but also a higher pressure drop. Therefore, the plate design should be chosen based on a balance between these two factors.

Material Selection

The choice of material for your plate heat exchanger is another important factor. Heat exchangers are available in a variety of materials to suit different types of fluids and operating conditions. For instance, stainless steel is a common material used for its corrosion resistance and durability. However, if the fluid is highly corrosive, titanium or other special alloys may be required.

Manufacturer and Supplier

Choosing reputable plate heat exchanger manufacturers is crucial. The leading plate type heat exchanger manufacturers are known for quality and innovation. If you’re in the UAE, finding a reliable plate heat exchanger supplier in UAE is essential for after-sales service and support. It’s also important to consider the manufacturer’s experience and track record in the industry.

Cost and Efficiency

While the initial cost is a factor, the overall efficiency and lifespan of the plate heat exchanger should also be considered. An exchanger may have a higher upfront cost, but its efficiency and durability often result in lower total cost of ownership. It’s also worth considering the potential energy savings from using a more efficient heat exchanger.

Conclusion

Selecting the right plate heat exchanger, such as an Alfa Laval heat exchanger, is a meticulous process that requires a deep understanding of your specific application. It involves careful consideration of the design and material of the plates, as well as a thorough evaluation of the manufacturer and supplier.

While the initial cost of the heat exchanger is an important factor, it is essential to consider the overall efficiency and lifespan of the product. A high-quality Alfa Laval exchanger, despite its higher upfront cost, often results in a lower total cost of ownership due to its superior efficiency and durability.

The right plate heat exchanger supplier can make all the difference in ensuring you get the best performance and service from your heat exchanger. Whether you’re one of the plate heat exchanger manufacturers looking to innovate or a business seeking the most efficient heat transfer solution, there are a range of heat exchangers available in the market, including those from Alfa Laval, to meet your needs.

Choose wisely, and you’ll be well on your way to achieving optimal heat transfer efficiency in your application. Remember, the goal is not just to find a heat exchanger that fits your budget, but one that also offers the best value for your investment in the long run, like an Alfa Laval exchanger.

In the end, the right plate heat exchanger, such as an Alfa Laval heat exchanger, will not only meet your heat transfer needs but also contribute to the overall efficiency and success of your operations. So, take your time, do your research, and make an informed decision. Your operations will thank you for it.