Pellets are small pieces of raw material used to either mold them into new shapes, or to be used as pellets. Usually, animal feed is mixed and made into pellets fed directly to the animals. When buying a machine that makes these pellets, the buyer should consider many factors. The article gives an insight on how to buy the best pellet maker.

Small industries have been on the rise in the past decade. People are trying to capitalize on the small gaps in their local markets by setting up shops to cater for the market needs. The machines are getting portable and cheaper as a side effect of such a demand. Whether you are looking for a big industrial setup or a small setup, the market has many different options available for the customers.

When buying a machine to set up a pellet making operation, there are a few fundamentals. Like any other processing machine, the consistency of quality output matters the most. To get the best machine for your operation, below are some factors.

Raw material

For any processing machine, be it a saw, a roller, or a pellet maker, the most important thing is the input raw material. The type of pellets you want to make will decide the raw material you need. Choosing the machine designed for the specific raw material is very important. The proper use of the device will determine how long your investment will give you returns.

Built quality

Do you know why German and British heavy industry equipment is sought after even though they charge a lot? They sell the best-made machines, which last you a lifetime with regular maintenance. The build quality can be measured by looking at a detailed statistic, the average output before it requires complete machine maintenance. The higher the yield, the better the built quality.

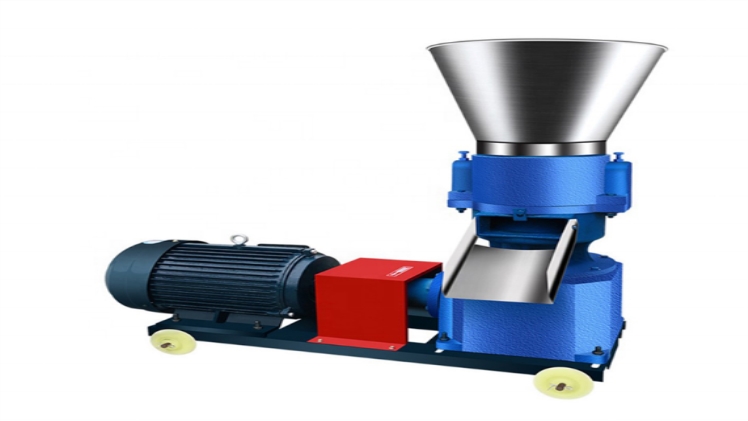

Parts of the Machine

A pellet making machine has five parts to it. The input funnel, output bay, control unit, pallet mold, and the motor.The more rigidity and synchronization between these parts, the better the machine’s built quality.

Reliable Manufacturer

The path to finding the best manufacturer for your requirement is easy. If you are looking for a brand, see their credibility and check the after-sales services. See to it that you select the best one for your business.

If you are looking to buy from a workshop which can make a machine for you, then check their credibility in the community. Before you give the order, look at their facility, and see how they manufacture. An organized production line will produce a good product. Lastly, inquire about the previous works they have done and how they are performing.

Ease of operation

Machine Manufacturers today are making user-friendly interfaces for industrial machines. The operator’s life becomes very easy if the device is easy to use. If you buy a small machine not operated by software, even those machines should have easy to follow steps for operation and troubleshooting.

Price of the machine

Depending on the size of the operation you want to set up and the output yield you need, the price will be determined. If money is not an issue, then it would be preferable to purchase from a brand with a good after-sales contract. If you are tight on budget, consider an engineering workshop in your local area to provide you with the machinery.

Conclusion

When purchasing a pellet maker, each point is based on a scale. It is not exact on taking this and leaving that. When purchasing the machine, it is paramount that you balance the rankings according to your needs and find the best machine for your pellet making operation.