Fiber optic cables are the present and the future. Once a domain dominated by copper trunk cables is being replaced by fiber optic cables. Since the data transfer happens in the form of light pulses, you get superior bandwidth and reliable data transfer that is free from any interference. Moreover, the overall size of a single fiber is thinner than human hair. Paired with outer protective cladding and jacket, it is still thinner than a copper cable. Thanks to the armored cover, you can protect the cable from rodents or water when installed in tight overhead ducts or buried underground.

How Fiber Optic works

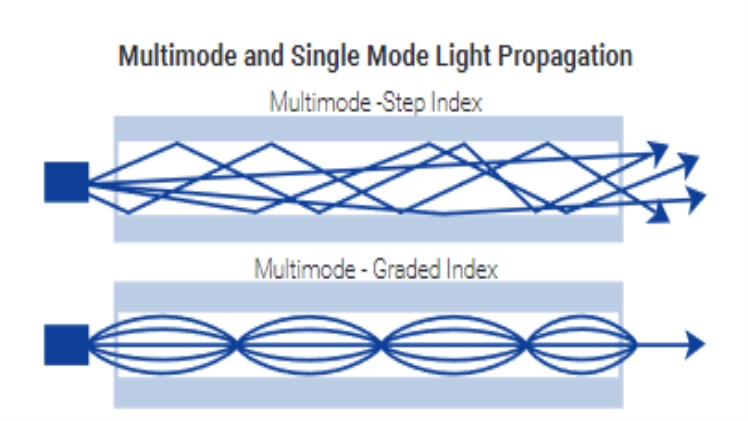

Contrary to the reliance on electric signals in the case of copper cables, fiber optic cables rely on light signals. The data to be transmitted is turned into light pulses with the ‘On’ and ‘Off’ states representing the ‘1’ and ‘0’ binary input. Made up of glass or plastic core with a protective cladding and plastic jacket, the pre-terminated fiber allows light pulses to travel through the medium. On the receiver end, the signal is turned back into data. Since the speed of light is greater than electric pulses, the data is transferred faster in fiber optics. Depending on the mode type (explained later), the light either travels parallel to the core or is constantly reflected at different propagation angles.

Benefits of Fiber Optic Cable Over Copper

- Better data transfer speed

- No electrical interference

- Very low chance of data loss when installed properly

- Durable

- Future-proof installation i.e., the components can be replaced without changing the cable while upgrading to a faster network

- Very high resistance to noise

- Doesn’t rely on repeater systems for distances up to 2kms

- Excellent security

- Can be shipped as pre-terminated fiber while placing an order

- Thinner and lighter than copper cables

- Resistant to water leakages

What is a Pre-Terminated Fiber Optic Cable?

In any network, the fiber optic cable is only the medium for the data to be sent across the transmitter and receiver. For a durable connection, it is important to have the correct connectors on both ends of the cable. The process of joining the connector to the end of a fiber or a copper is called termination. Just like with copper cables, technicians can terminate the ends after the cable is installed. However, you need to ensure that terminations are cleanly done and there is very low insertion loss (i.e., the drop in signal due to improper termination). Not only is field termination time consuming but the installation cost increases considerably due to increased labor and technicians needed on the site. Any improper termination means the cable needs to be redone.

Pre-terminated fiber, as the name suggests, is terminated before installation. Mostly the cables are shipped after terminating the ends in the factory itself. Not only are the cables terminated properly at predetermined lengths but they are also tested before being shipped to the site.

Benefits

- Factory grade precision: The cores are edge polished, and attached to the connectors with the right amount of epoxy to ensure low insertion losses.

- Less wastage: There is no worry for improper termination which may lead to excess wastage. Moreover, appropriate safety measures are implemented to keep the connectors protected.

- Minimum insertion loss: When terminated at the factory, precautions and additional measures are taken for attaching the connectors to cores that are free of material defects, smudges, or contamination.

- Space-saving terminations: The cables terminated at the factory can be bunched together in a trunk cable. This way, you can have multiple connections without occupying a comparatively larger space.

Types of Fiber Optic Cables

Depending on the light propagation method, fiber optic cable can be divided into two distinct types:

- Single-mode fiber optic cable

- Multimode fiber optic cable

Single-mode fiber optic is a single strand of very small diameter (8 – 9um). The light pulses travel in a straight line, parallel to the glass core. This way, the light signals can be transmitted to great distances (>24 miles) with minimum attenuation and signal loss. Hence these are used in long-distance information transmission.

Multimode fiber optic cable is a slightly larger strand of diameter (50um and 62.5um). The larger core diameter allows multiple light signals to be transmitted simultaneously. Yet, due to the attenuation caused by the constant reflection, these cables cannot be longer than 500mtrs. So, they are more preferred for medium-size enterprises or interdepartmental communications.

Types of Multimode Fiber Optic Cable

There are further two types of Multimode fiber optic cable depending on the core construction.

- i) Step Index

- ii) Graded Index

In step-index multimode, the core density is uniform with denser cladding around it. This allows the light signals to be scattered at the receiving end. So, it is predominantly used for illumination and imaging.

Graded index fiber optic cable, on the other hand, has a varying core thickness. So instead of being reflected across the core edge, the light is constantly refracted to follow a curved path. Due to this, the light originates and reaches the end at the same time. Depending upon the core thickness, the data bandwidth changes drastically. Based on the maximum supported bandwidth, you can buy 4 types of multimode fiber optic cable assemblies.

- OM1

- OM2

- OM3

- OM4

OM1 Multimode Fiber

The optical fiber with the largest core density of 62.5μm core thickness and 125μm cladding thickness, the OM1 Multimode fiber is used for 10 & 100Mbps and 1 Gigabit/sec networks. Due to the issue of attenuation, the maximum permissible cable length for Gigabit ethernet is only 275 meters. After that, the light signal experiences modal dispersion. For a light source of 1300nm wavelength, the length at which modal dispersion increases to 550 meters.

OM2 Multimode Fiber

OM2 fiber has a core thickness of 62.5μm core thickness and 125μm cladding thickness. It is a better choice for 1 Gigabit ethernet as the maximum permissible length is 550 meters.

OM3 Multimode Fiber

OM3 fiber also has a core thickness of 62.5μm core thickness and 125μm cladding thickness. It can be used for 10 Gbps and 100 Gbps Ethernet networks where the cable length is 300 meters (10Gbps) and 100 meters (100Gbps).

OM4 Multimode Fiber

OM4 fiber also has a core thickness of 62.5μm core thickness and 125μm cladding thickness. Due to the superior construction, it is efficient in cutting down the modal dispersion to 150 meters for a 100 Gbps Ethernet network. So it is a better choice for the 100 Gbps Ethernet network.

Wrapping Up

When upgrading an existing network or planning for a network layout from scratch, fiber choice is vital. Going for pre-terminated fiber optic cables, you save time, cut down on the installation costs, and have your network up and running in no time. The only preparation would be to have the network layout planned and correct measurements are provided with placing an order.