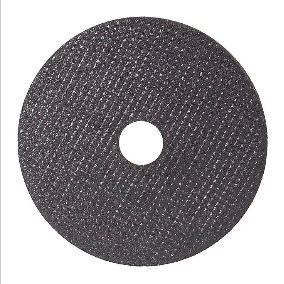

Cutting disc is a flat, thin round disk-like made from a solid abrasive disc that looks similar to compact discs. It is used with angle grinder machines to cut through hard, thick metal such as aluminum and steel. There is a lot of ease and control when using a cutting disc with an angle grinder.

The abrasive cutting discs are made for metal fabrication. Also, industries like automotive, food processing, and pharmaceuticals use cutting discs since it is safe and cost manageable. Different cutting discs are made for various applications and requirements. Choosing the right cutting disc assures your safety and maximizes efficiency, and gives desired results.

Variety

Abrasives are sharp, hard materials used to wear away working pieces like metal. Syn abrasives have been developed, adding to the current existing natural abrasives. It has brought about manufactured varieties like Aluminum Oxide, Silicon Carbide, Cubic Boron Nitride, and Diamond that have been developed in that order, with each release harder than the previous one.

Wide Application

Unlike a most cutting discs, abrasive cutting discs are not limited to specific material. They can work on almost everything. Its development technology facilitates it. Each wears out exposes new fresh cutting material called the abrasives, making it easy to cut up different materials like metal, ceramic, fiberglass, concrete, pipes, etc. This makes it economical especially in construction sites where a lot of cutting is done.

Safe to Use

The abrasive cutting discs use erosion technology where every cut is made when the cutting disc is eroded, exposing new fresh cutting materials. The abrasives are very tiny; hence, the wear-off is slow and does not pose a danger to the user. Some cutting discs may develop weak points and break while cutting, posing a significant threat to the user.

Economical

Cutting discs are quite a lot in the market, all made of different materials that are expensive to buy at times. For the abrasive cutting disc, its price is relatively low compared to the other types making it the most affordable. It has brought a balance at the cutting disc price in Kenya, where one can get cheap and durable cutting discs without selling an arm.

Desirable results

The abrasive cutting disc does ensure that you achieve precise cutting and into any desired angle. It leaves a smooth, even surface after cutting hence saving the grinding time and making it easy to join the metal together. It is enabled by the eroding technology applied in abrasive cutting discs. Making it the most desired and sort-after cutting disc in the country.

Durable.

This non-reinforced abrasive cutting disc comprises many sub-micron cutting particles that get exposed, ready to cut when the other gets worn-off. These will ensure a continuous presentation of fresh, new prepared-to-cut material with every cut, hence making it unique all the time—no need to worry about sharpening it. Durability is only affected when a light cutting is used to cut a heavy metal.

Conclusion.

Abrasive cutting discs are the new most affordable way of getting smooth-edged cutting with durability and convince of acquiring it. With its wide variety of sizes, you can be sure it can fit in different machines at the user’s convenience. There is a disc for every other material ranging from coarse-grained abrasive for weighty metal to excellent grained abrasive material for very light material.