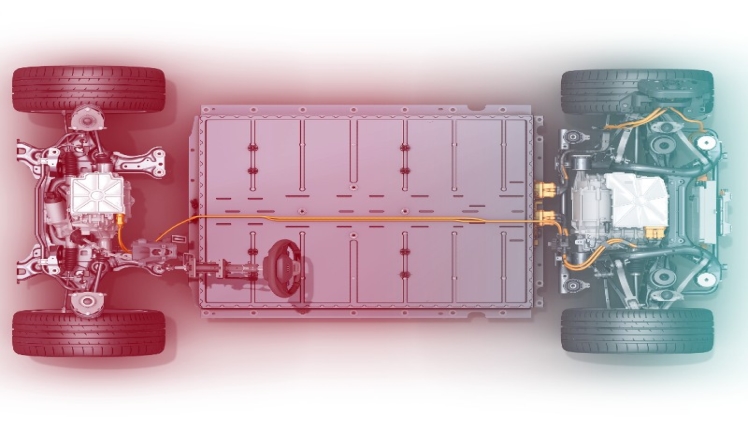

A Li-ion electric battery should not surpass the core temperature from 80 to 90°C. These reasonable levels are not produced by coincidence, however: they are the product of battery thermal management and combine heat dissipation and power regulation. What are the techniques of dissipating the heat in particular?

Why should the heat produced by a used battery be removed?

A module pack consists of a battery pack which consists of cells themselves. Each cell has a limited amount of power and manufacturers have the problem of designing batteries with the best energy density. We have the best EVB tape for you.

Inevitable heat production

Unforgettable creation of heat

Electrical batteries generate heat naturally because exothermic chemical processes occur. Thus, the stronger a battery is, the more heat it emitts. Therefore the dissipation of the calories of an electrical battery is twofold:

- Limiting component thermal ageing;

- enhance the amount of energy each cell can create.

The charge/discharge range is between 20 and 80 percent for electric car batteries. Energy density: the electrical quantity that can be held for a particular volume. Density of power: how fast the battery can supply power. For flooring systems, please visit our site.

Materials Used

There are several materials that can eliminate the calories produced by electric battery cells after they are chopped and functionalized. It should nevertheless be remembered that a good electric insulator is seldom an efficient thermal conductor

Films with thermal conduction

The main function is electrical insulation, which is the relatively low thermal conductivity of most commercial films, never more than 0.2 W/mK. Nevertheless, the thermal conductivity of products such as Kapton® MT+ is around 0.75 W/mK. In any event, a number of film kinds may always be overlaid to build a superior, multi-layered substance.

Thermal adhesive tapes

Thermal stickers

These thermal tapes are composed of excellent thermal conductivity adhesive masses (1 to 2 W/mK). They have two roles:

- Mechanical assembly; •dispersion of heat.

Thermal Pads

The heat conductivity of these flexible silicone or acrylic products is at times above 3, or even 4 W/mK. When cut to the correct size, the cooling plates and heat sink can be interspersed between battery cells, as in the electronics. In addition, dielectric foams can insulate the cells from one other. These materials, known as compression pads, enable thermal contact and an optimum heat dissipation by keeping cell pressure constantly

Thermal mastics and pastes

Mastics and pastes are administered with a syringe or similar instrument because of their consistency. They can be utilised to disperse heat between a cooling system and battery pack. More information click here jio rockers

Liquid Products

Liquid thermal conductors, often known as gap fillers, are accessible since they are used to replace empty gaps. The air is a very excellent thermal isolator that allows for the removal of bubbles. There are also liquid adhesive thermal conductors.

Conclusion

Heat generation is unavoidable with electric car batteries. It can be removed with film materials, adhesive bands, pads, thermal mastics or liquid solutions. This heat is dispersed. For more info visit here movierulz